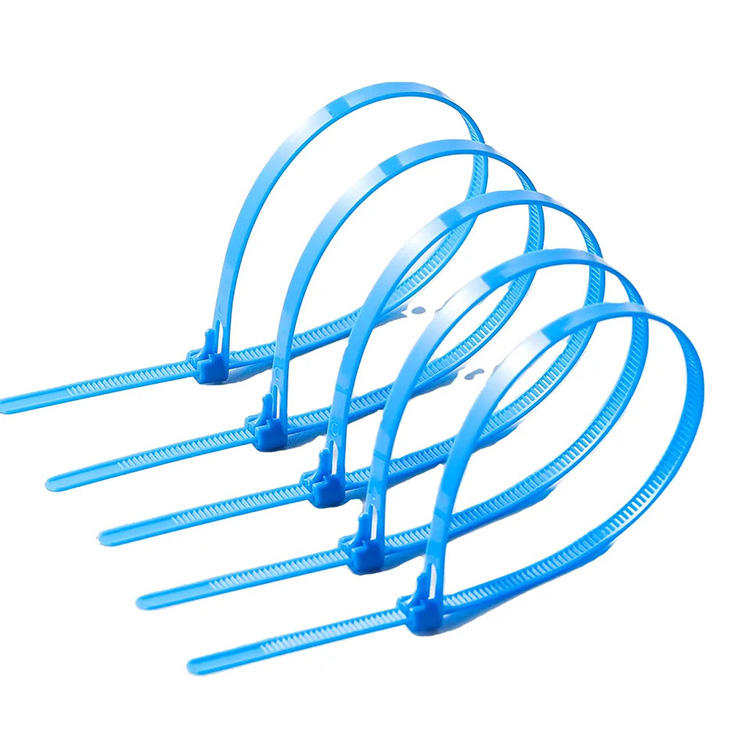

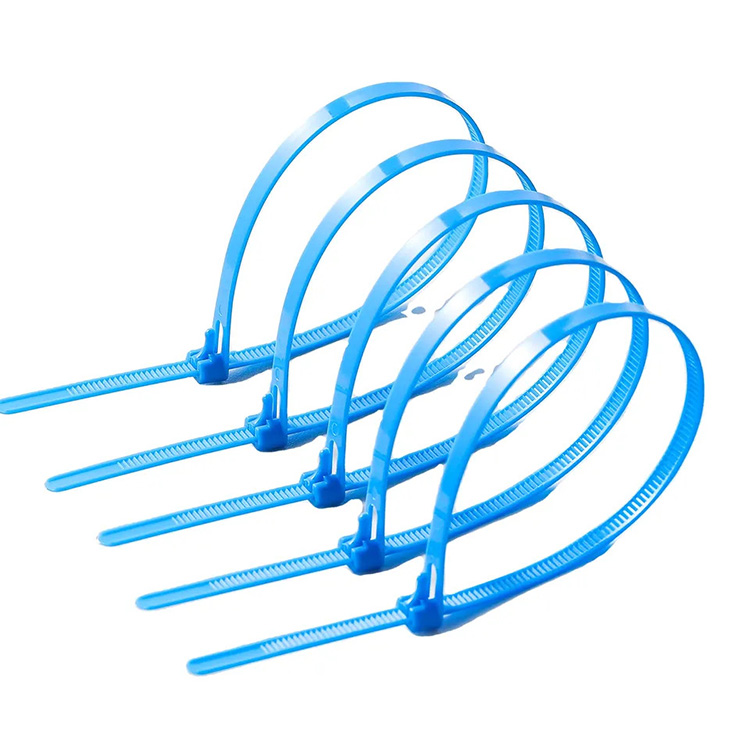

PE Wiring Wrapping Band

China YAGE PE wiring wrapping bands, also known as polyethylene wiring wrapping bands, are flexible bands made of polyethylene (PE) material that are used to bundle and organize wires and cables. These bands are commonly used in electrical and telecommunications installations to secure and protect cables.

Send Inquiry

PE wiring wrapping bands

YAGE PE wiring wrapping bands are designed to be durable and resistant to environmental factors such as moisture, UV radiation, and temperature variations. They provide a reliable solution for managing and securing wires in various applications.

These bands are typically available in different widths and lengths to accommodate various cable sizes and bundling requirements. They can be easily wrapped around a group of cables and secured using their inherent flexibility and self-gripping properties.

The primary purpose of PE wiring wrapping bands is to keep wires and cables organized, preventing them from becoming tangled or loose. They provide a neat and professional appearance while also offering some level of protection to the bundled cables.

PE wiring wrapping bands are commonly used in electrical panel installations, network racks, and cable management systems. They are particularly useful when dealing with a large number of cables that need to be organized and secured together.

One advantage of PE wiring wrapping bands is that they can be easily removed or adjusted when necessary, allowing for modifications or additions to the cable setup without the need for cutting or re-tying.

Overall, PE wiring wrapping bands are a practical solution for bundling and managing cables, offering durability, flexibility, and ease of use in various electrical and telecommunications applications.

PE wiring wrapping bands Feature And Application

YAGE PE wiring wrapping bands, also known as PE cable ties or wire wraps, are versatile and flexible accessories used for bundling and securing wires, cables, and other items together. Here's what you need to know about these wiring wrapping bands:

Material: PE (Polyethylene) is a common material used for wiring wrapping bands. It is a durable and flexible plastic that offers good resistance to moisture, chemicals, and UV radiation.

Design: PE wiring wrapping bands typically consist of a flat, elongated strip with a series of evenly spaced teeth or ridges along one side. The strip can be wrapped around a bundle of wires or other items, and the teeth or ridges interlock to securely hold the band in place.

Cable Management: PE wiring wrapping bands are primarily used for cable management and organization. They provide a neat and tidy solution for bundling and securing wires, preventing them from tangling, and reducing the risk of tripping hazards.

Versatility: These bands are versatile and can be used in various applications beyond cable management. They can be used to bundle hoses, cords, tubing, or any other items that need to be kept organized and secure.

Installation: To use PE wiring wrapping bands, you simply wrap the band around the items to be secured and pull it tight. The teeth or ridges interlock to create a secure hold. Some bands may have a buckle or fastening mechanism for easy installation and adjustment.

When using PE wiring wrapping bands, consider the following:

Size and Length: Choose the appropriate size and length of the band to ensure it can comfortably wrap around the items you need to secure. Consider the diameter and number of cables or the size of the items being bundled.

Reusability: Some PE wiring wrapping bands are reusable and can be easily opened and adjusted when needed. Check the product specifications to determine if they can be reused or are single-use.

Tension and Tightness: When securing the band, apply enough tension to hold the items securely but avoid over-tightening, which could potentially damage the cables or items being bundled.

PE wiring wrapping bands are an effective and economical solution for cable management and bundling needs. They provide a secure and adjustable method for organizing and securing wires, cables, and other items in a wide range of applications.