304 Stainless Steel Cable Ties

At china YAGE factory, we understand that each customer has unique requirements for 304 Stainless Steel Cable Ties. Therefore, we strive to deliver products that meet those specific needs and exceed expectations in terms of quality, performance, and affordability. Our 304 Stainless Steel Cable Ties have received positive feedback from many satisfied customers around the world, which is a testament to our commitment to excellence. If you are looking for a reliable and durable solution for your cable management needs, please don't hesitate to contact us for more information about our 304 Stainless Steel Cable Ties.

Send Inquiry

304 Stainless Steel Cable Ties

304 Stainless Steel Cable Ties are a type of cable tie made from high-quality stainless steel material. These cable ties are known for their strength, durability, and resistance to corrosion, making them ideal for use in harsh and corrosive environments.

The 304 stainless steel material is also non-magnetic, making it suitable for use in electrical and electronic applications where magnetic interference must be avoided. Additionally, these cable ties have a high tensile strength, which ensures a secure and reliable hold on cables and wires.

304 Stainless Steel Cable Ties are commonly used in various industries, including aerospace, automotive, marine, and oil and gas. They are also suitable for applications where hygiene is critical, such as in the food and beverage industry.

304 Stainless Steel Cable Ties Feature And Application

Applications:

Ideal for petrochemical, Industries, power stations, mining, ship-building, offshore, and other aggressive environments.

Product Features:

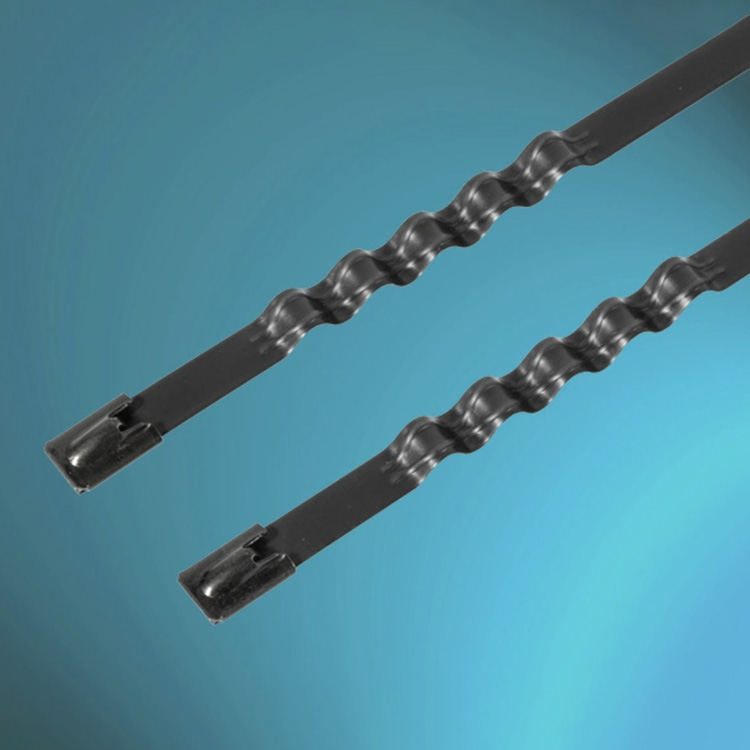

a: Coated band with non-toxic, halogen free polyester coating

b: Provides additional edge protection

c: Prevents the corrosion between dissimilar materials.

d: Metallic buckle helps to distinguish from black nylon tie

Technical Information:

Material: Stainless Steel Grade 304 or 316

304 grade stainless steel, for standard applications

316 grade stainless steel, for extra corrosive environments

Working Temp.: -50ºC to 150ºC

Description: Black Band with Metallic Buckle

Flammability: Fireproof

Other Properties: UV-resistant, non toxic

304 Stainless Steel Cable Ties species

Here are some common species of 304 Stainless Steel Cable Ties:

1. Standard Stainless Steel Cable Ties: These are the most common type of stainless steel cable ties and are used for general cable management. They are ideal for use in harsh environments where corrosion resistance is required.

2. Coated Stainless Steel Cable Ties: These cable ties are coated with a layer of nylon or polyester to provide additional protection against corrosion and to reduce noise when installing.

3. Releasable Stainless Steel Cable Ties: These cable ties can be easily released and reused, making them a more sustainable and cost-effective option. They are commonly used in situations where cables need to be frequently added or removed.